close

Bulletproof aramid UD fabric is a kind of composite material made of aramid fiber impregnated in resin matrix, and adopts 0°/90° orthogonal composite into two layers of continuous sheet coil. Compared with traditional bullet-proof materials (woven fabric, knitted fabric, woven fabric, etc.), bullet-proof UD fabric has significantly improved in terms of forming structure, processing technology and elastic resistance, and is one of the world's top bullet-proof materials. The long fibers in the weft less cloth are arranged in the matrix material straight and parallel, and there is almost no strength loss of the fibers during processing, so the design can give full play to the fiber itself of high strength, high modulus, low density, aging resistance, wear resistance and other properties, greatly improving the energy transmission efficiency and impact resistance. Therefore, it is one of the preferred solutions for lightweight soft body armor inner core. The inner liner using this material can effectively reduce the concave deformation on the back side, avoid blunt injury caused by excessive concave, and provide good protection against shooting threats in various environments. At present, lightweight aramid UD fabric has been widely used in flexible body armor, which effectively improves the rapid response and protection ability of the army.

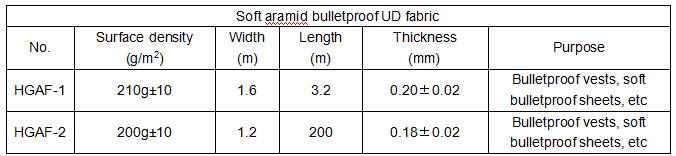

Product specifications:

Main characteristics: